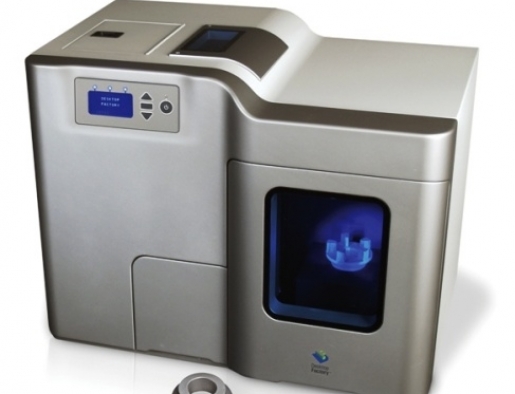

3D printers were born in the mid-nineties when two MIT researchers developed the technology to print in a new dimension. 3D printers were initially developed to convert CAD files into real prototypes of the designs.

These 3D printers print in layers spreading a layer of powder and printing where needed, the process is repeated until the piece is finished. Today, 3D printers cover a wide range of technologies used to manufacture from prototypes to models of buildings and CAD design files.

The main technologies capable of printing in 3D are:

• DSPC (Direct Shell Production Casting ): The 3D printing process works via a printhead moving over a fine layer of alumina powder, depositing a liquid binder layer-by-layer to define a cross section of the mold. The process is repeated until the entire mold is printed.

• SLA (Stereolithography): This system projects an UV laser to a photosensitive liquid resin causing polymerization.

• SGC (UV photopolymerization): Similar to the stereolithography technology. It works by the solidification of a photopolymer or photosensitive resin with a high UV lamp power.

• FDM (Fused deposition modelling): This technology bases its operation on a thread of material at 1 ° C that moves horizontally in the XY plane with the aid of a nozzle. This thread solidifies immediately by touching the previous layer.

• SLS (Selective Laser Synthesizing): is an additive manufacturing technique that uses a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic, metal (direct metal laser sintering), ceramic, or glass powders into a mass that has a desired three-dimensional shape.

• LOM (aminated Object Manufacturing): 3D printing system consist of a feed mechanism on that advances a sheet over a build platform, a heated roller to apply pressure to bond the sheet to the layer below, and a laser to cut the outline of the part in each sheet layer.

Víctor Ramos is Community Manager at Mijo! Brands in Mexico.

Click here to read more about current trends.